We produce the high quality and efficient pneumatic conveying system that the characteristics of the powder/pellet are suited.

Sanko Air Plant Ltd.

We produce the high quality and efficient pneumatic conveying system that

the characteristics of the powder/pellet are suited.

To download the files,

you must register your e-mail address.

Download PDF version product information

To open our PDF version leaflets, you need to install Adobe Reader.

Sanko Air Plant Ltd.

- Yodoyabashi Mitsui Bldg. 4-1-1, Imabashi, Chuo-Ku, Osaka 541-0042, Japan

- TEL: 81-6-6231-3351

- FAX: 81-6-6222-2657

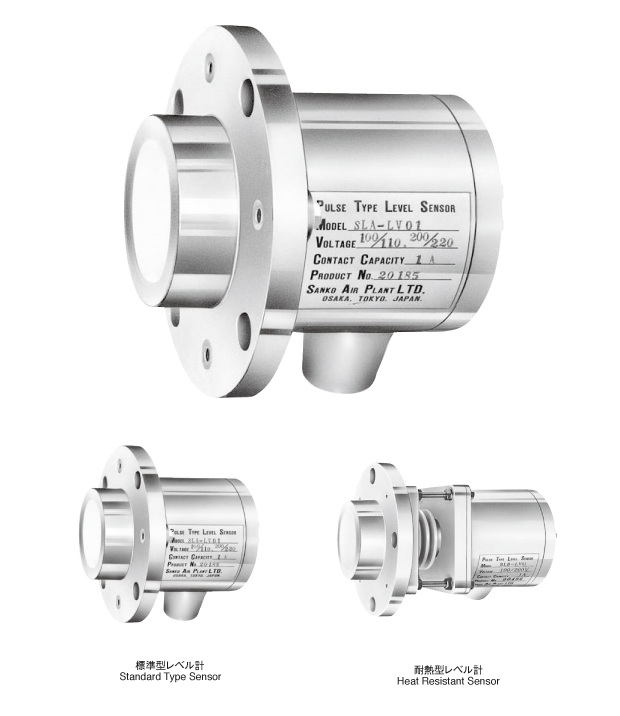

Level Sensor

Pulse Type Level Sensor

Introduction

Features

The face of the sensing disk has no protruding parts and the sensor unit itself is flush-mounted on the inside wall of the structure for ease of cleaning of the inside wall of the structure and to eliminate the risk of bridging of the process material in the structure. For the same reason, the sensor unit does not undergo any local load that may damage it or cause malfunction. The process material does not stick to the sensing disk even if it is viscous, thus ensuring stable operation at all times.(The sensor can tolerate up to 10mm of material buildup on its sensing disk.) The sensor is compatible with a small-capacity hopper, or even a chute. The sensor unit does not require any adjustment of its sensitivity to conform to changes in ambient temperature, humidity or the type of process material. A change in pressure in the structure does not cause malfunction of the sensor unit. Few mechanical parts mean extended service life. The sensor can be adapted to a mixer-mounted tank, as long as minimum of 50mm is provided between the impeller and the sensing disk.

To download the files,

you must register your e-mail address.

Download PDF version product information

To open our PDF version leaflets, you need to install Adobe Reader.

Sanko Air Plant Ltd.

- 4-11, 3 Chime, Dosho Machi,Chuou Ward, Osaka City 541-0045(Shin Shibakawa Bldg.)

- TEL: 81-6-6231-3351

- FAX: 81-6-6222-2657