We produce the high quality and efficient pneumatic conveying system that the characteristics of the powder/pellet are suited.

Sanko Air Plant Ltd.

We produce the high quality and efficient pneumatic conveying system that

the characteristics of the powder/pellet are suited.

To download the files,

you must register your e-mail address.

Download PDF version product information

To open our PDF version leaflets, you need to install Adobe Reader.

Sanko Air Plant Ltd.

- Yodoyabashi Mitsui Bldg. 4-1-1, Imabashi, Chuo-Ku, Osaka 541-0042, Japan

- TEL: 81-6-6231-3351

- FAX: 81-6-6222-2657

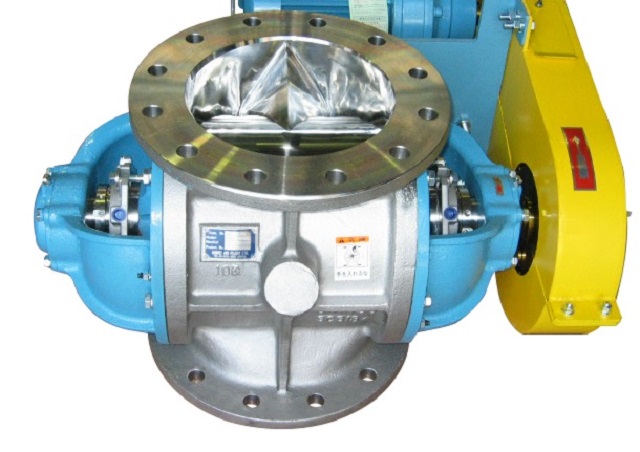

Rotary Feeder (Single)

Special specification type / Mechanical seal type

Replacing with grand packing and In order to prevent gas leak and powder leak completely, Rotary feeder can be equipped with a mechanical seal.

An economical running cost is realized and it is an eco-friendly Rotary feeder.

Application:

The rotary feeder for fine powder

The rotary feeder which deals with gas other than air

Operating condition:

Pressure: ~0.1MPa

Temperature: ~160℃

Notice:

Please let us know if you want to attach a mechanical seal with the existing rotary valve

Shaft seal part feature

Cartridge-type dry mechanical seal

Feature

Gas leak and powder leakage 0 from shaft seal part Mixing the abrasion powder and the oil of the ground gasket etc. is 0. Decrease of amount of shaft seal Purge Operation It is possible to drive continuously for 8000 hours or more without maintenance by the dry, mechanical seal use.

Merit

Decrease of Maintenance work and cost Decrease of expensive Purge Operation consumption Quality degradation prevention of product by foreign body mixing 0 Environmental reform around machine because of powder leakage Safety measures by gas leaks such as the toxic gas or nitrogen gas (lack of oxygen)

To download the files,

you must register your e-mail address.

Download PDF version product information

To open our PDF version leaflets, you need to install Adobe Reader.

Sanko Air Plant Ltd.

- 4-11, 3 Chime, Dosho Machi,Chuou Ward, Osaka City 541-0045(Shin Shibakawa Bldg.)

- TEL: 81-6-6231-3351

- FAX: 81-6-6222-2657