We produce the high quality and efficient pneumatic conveying system that the characteristics of the powder/pellet are suited.

Sanko Air Plant Ltd.

We produce the high quality and efficient pneumatic conveying system that

the characteristics of the powder/pellet are suited.

To download the files,

you must register your e-mail address.

Download PDF version product information

To open our PDF version leaflets, you need to install Adobe Reader.

Sanko Air Plant Ltd.

- Yodoyabashi Mitsui Bldg. 4-1-1, Imabashi, Chuo-Ku, Osaka 541-0042, Japan

- TEL: 81-6-6231-3351

- FAX: 81-6-6222-2657

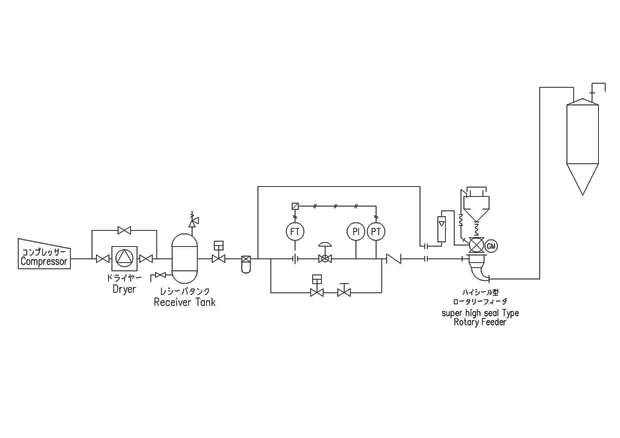

Pneumatic Conveying System

Plug Flow Dense Phase Conveying System

The Plug Flow conveying is one of conveying system that powder/pellets moves while forming the group like plug(slug), without floating. This conveying system has a little air consumption and high conveying efficiency , decreasing the conveying material crushing and piping abrasion . Also, there is no occurrence of streamer in case of resin pellet conveying.

Features

The gas velocity which can form plugs changes with conveying pipe size, particle size, bulk density, gas density (pressure) etc. In case of polyolefin (for example polypropylene) pellets conveying, the gas velocity is a standard in 10m/sec or less. On the occasion of actual design, the range of gas velocity will be designed 2~8 m/s. In the case of powder conveying, proper gas velocity is lower about 40%~50% than the case of pellet.

Applications

The Plug Flow system is called commonly High Pressure System, because it is frequently applied to long distance conveying that it is required high pressure which is used compressor as air source. However, conveying pressure depend on conveying distance. Even pressure becomes low, if distance is short. In this case, roots blower can be applied with stabilize conveying. Also we can adopt standard (for low pressure) rotary feeder(or blow tank for low pressure) as conveying feeder in this Plug Flow System.

To download the files,

you must register your e-mail address.

Download PDF version product information

To open our PDF version leaflets, you need to install Adobe Reader.

Sanko Air Plant Ltd.

- 4-11, 3 Chime, Dosho Machi,Chuou Ward, Osaka City 541-0045(Shin Shibakawa Bldg.)

- TEL: 81-6-6231-3351

- FAX: 81-6-6222-2657